Research

"Truth is what stands the test of experience." - Albert Einstein

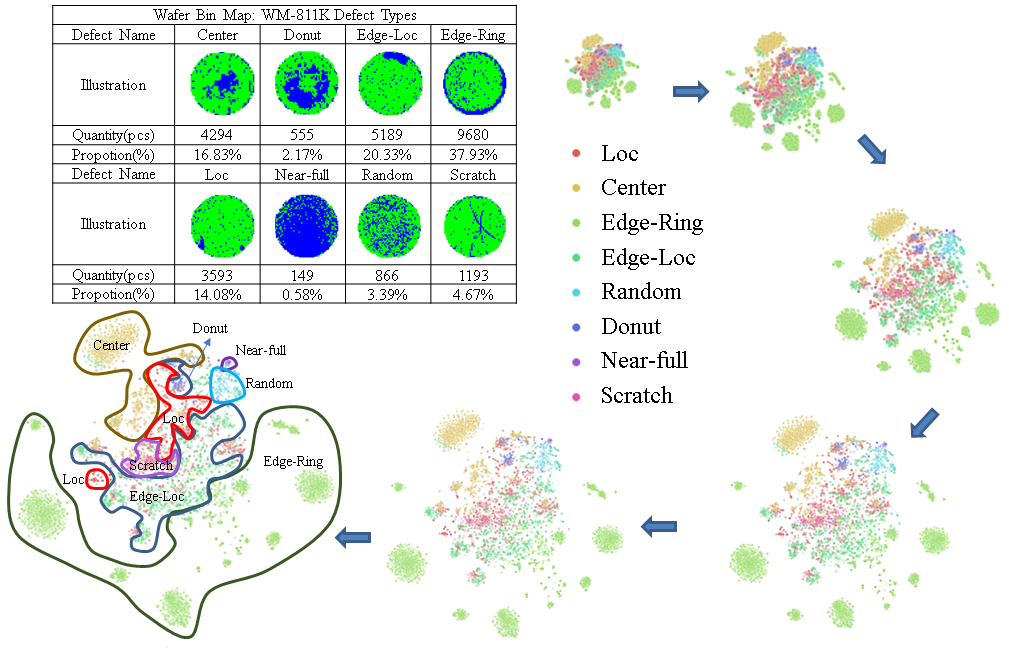

Data Science in Manufacturing (製造數據科學)/ Intelligent Manufacturing

Systems (智慧型製造系統)

|

Manufacturing

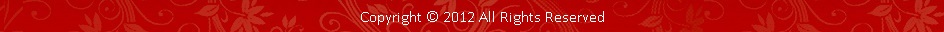

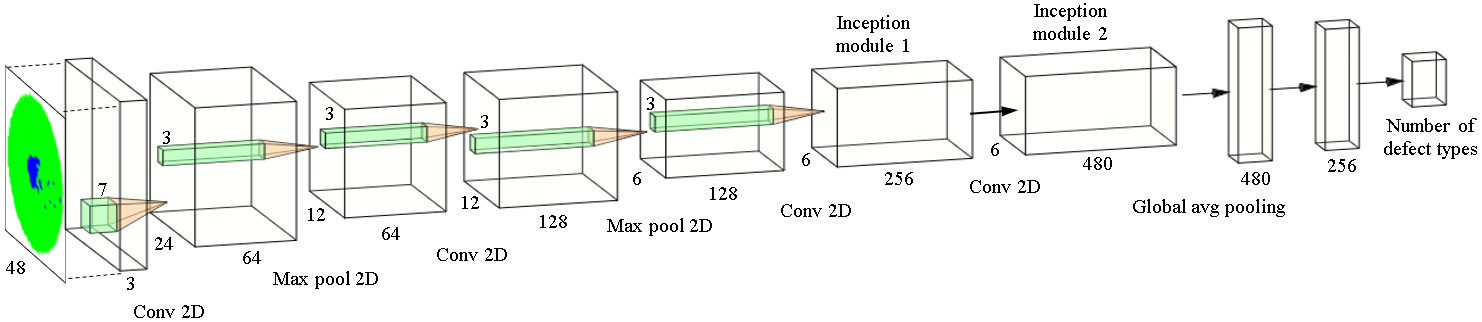

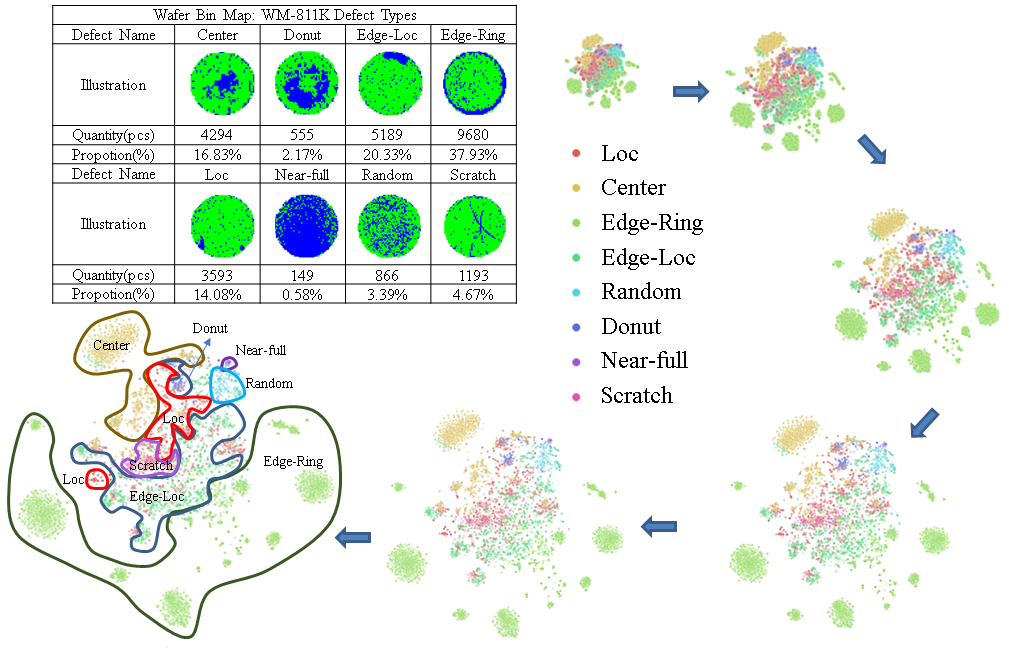

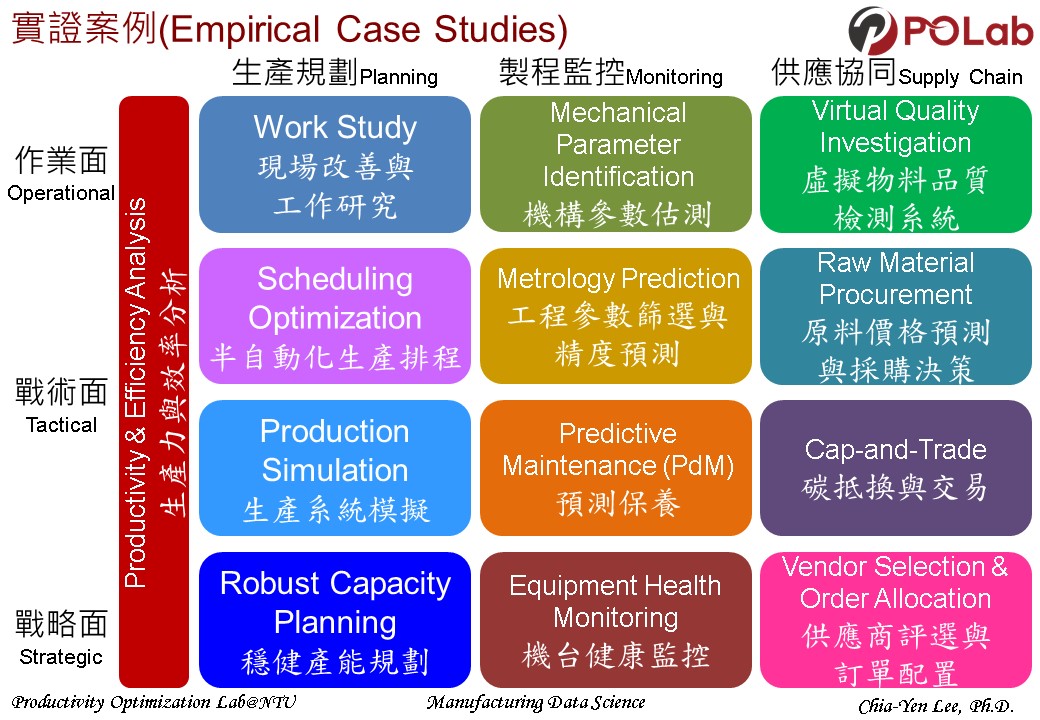

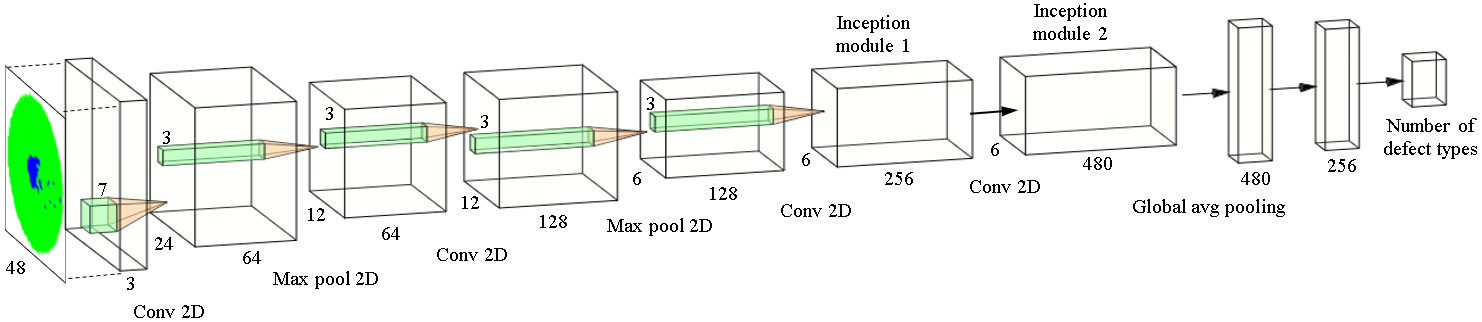

Data Science (MDS) is a decision-oriented system which has the

computational

intelligence and self-learning ability to optimize the manufacturing

process. The

techniques include data science (decision tree, deep learning, feature

engineering, clustering, etc.), meta-heuristic algorithms (e.g. tabu

search,

simulated annealing, genetic algorithm, particle swarm optimization,

etc.),

fault detection & classification (FDC), statistical process control

(SPC), engineering data analysis (EDA), etc. These

methodologies can optimize resource allocation and support

trouble-shooting process. The applications are diversified such as

capacity planning, production scheduling, machine configuration

optimization, process fault diagnosis, facility layout, bottleneck

identification, quality and yield enhancement, market

segmentation,

pattern recognition, etc. Real-setting empirical studies were conducted

to validate the proposed model and improve the business core competence

effectively.

Research Interests:

|

Productivity and Efficiency Analysis (生產力與效率分析)/ Production Economics (生產經濟學)

|

|

|

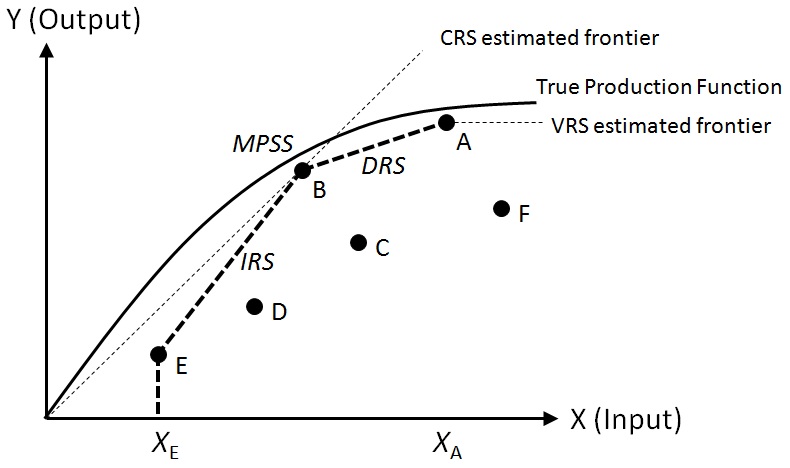

Productivity

and

efficiency analysis (PEA) is a discipline to assess

the performance of production system and drive productivity. The

technique is developed to estimate production function based on

production economics and then the efficiency of production system can

be identified. PEA supports evaluating the productive efficiency,

productive

effectiveness, product mix,

scale size, productivity change, performance benchmarking, market

power, etc. The research focuses

on developing nonparametric method (e.g. Data Envelopment Analysis,

DEA) and

semi-parametric method (e.g. Stochastic semi-nonparametric envelopment

of data,

StoNED) applied to the areas of manufacturing, airlines, energy market,

power system, cap-and-trade, carbon emission, biofuel diesel, etc.

Research Interests:

|